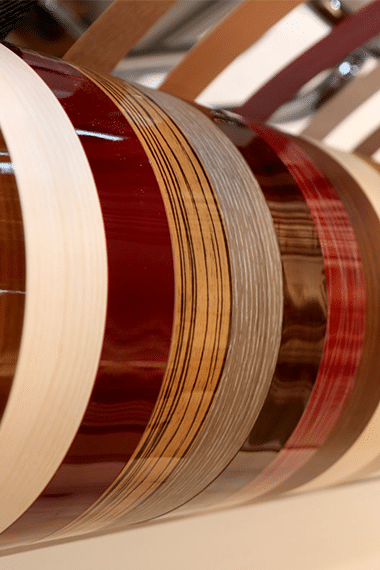

Edge Banding

ESI is Doelken’s largest distributor of edge banding in North America. With factories, service centers, and distribution partners throughout North America, Doellken-Woodtape is uniquely suited to quickly and conveniently supply edge banding products and services to the industry. The company’s extensive edge extrusion technology and more than 50 years of experience ensure a high standard of quality and service.

The Doellken-Woodtape product offering suits individual furniture designs and meets the demand of environmentally conscious furniture manufacturers. Doellken-Woodtape has the most complete edge banding stock program for the woodworking industry.

PVC Edge Banding

As North America's largest PVC edge banding distributor, ESI has a long history of great service, excellent products, and a wealth of experience in all facets of our industry. All this combines for the most comprehensive edge banding offering for the cabinetry and furniture industries. With nine stocking locations across the United States, we can offer you the best selection, deepest inventories, and helpful personal attention.

To assist you finding the right edge banding match, we encourage you to use our PVC Pattern Search Tool. You can cross reference all major laminates and melamines. It's fast and easy!

As always, feel free to call your nearest ESI location if you have any questions.

REHAU LaserEdge™

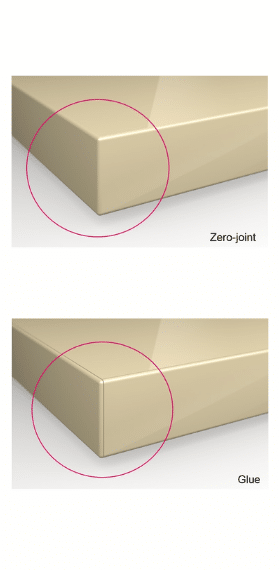

REHAU LaserEdge™ is edge banding with a pre-applied, co-extruded polymer functional layer that replaces the traditional glue used to apply edge banding, allowing for a superior bond and a seamless joint between the edge banding and the board.

Coming in a 1.2mm thickness (1mm after application), this product consists of a .2mm functional glue layer made of polypropylene that doesn't "stick" to the board but melts into and truly "bonds" with it. The 1mm decorative top layer is made of ABS coated with a finish to protect from fading, water damage, and scratches, making this product environmentally friendly, incredibly strong, long-lasting, and better looking. Overall it is superior to any other type of edge banding both functionally and aesthetically.

Running LaserEdge™ on the latest laser, hot-air, plasma, or NIR edgebanders requires no glue purchasing, no glue pot maintenance, and no glue mess to clean-up after application leaving a near-invisible glue line that will never shrink or swell. With no extra adjustments required on an edgebander qualified to run LaserEdge™ material, allowing you to quickly and easily achieve seamless joints and superior finishes, LaserEdge™ can vastly improve your shop's productivity and finished product.

Note: This material can only be used with hot-air, laser, plasma, or NIR edgebander machines. For an unbreakable bond and a virtually invisible joint that will look better and last longer than any other edge banding without the hassle of glue purchasing, clean up or maintenance, ask ESI about REHAU LaserEdge™.

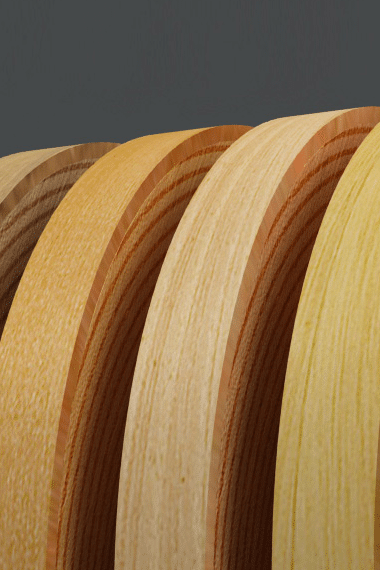

Wood Edge Banding

LEADING THE INDUSTRY IN VENEER MICRO JOINT TECHOLOGY

State-of-the-art equipment and technology combined with raw veneer resource management produces a range of veneer products unmatched in the industry.

The use of coiled veneer products has become an integral component of real wood edge treatments within the industry. The manufacturing advantages and the economies derived from the use of coiled veneer offer substantial benefits, including simplified inventory control, minimized waste, and the maximum utilization of valuable natural resources. Now, ESI is pleased to offer the breakthrough Micro Joint Technology.