Edge Banding

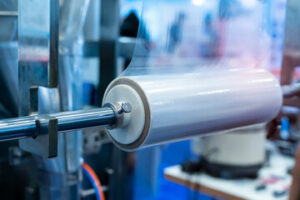

Edge banding covers the raw edges of furniture components, such as the particle board or MDF, with a thin strip. This strip, known as edge banding tape, is typically made of plastic, veneer, or wood and is applied to the edges of the furniture using heat and pressure.

The primary purpose of edge banding is to improve the furniture’s aesthetic appearance and protect the raw edges from chipping or peeling. It can also help to reduce the amount of debris that accumulates on the edges of the furniture. There are several different methods for edge banding furniture, including manual application with a hand-held iron, automatic application with a specialized machine, and self-adhesive edge banding tape applied with a roller or iron.

Regardless of the method used, the goal is to create a seamless, smooth transition from the edge of the furniture to the edge banding material. This requires precise application and careful attention to detail, as any gaps or imperfections will be visible once the edge banding is applied.

Edge banding is an important process in furniture production, as it helps improve the finished product’s overall appearance and durability.

Why Does Furniture Need Edge Banding?

There are several reasons why furniture manufacturers and designers may choose to use edge banding:

- Aesthetics: Edge banding can cover up unsightly raw edges and create a seamless, finished look for the furniture.

- Durability: Edge banding helps protect the furniture’s raw edges from chipping or peeling, which can extend the life of the furniture and improve its overall durability.

- Dust and debris reduction: Covering the raw edges of furniture with edge banding can help reduce the amount of debris that accumulates on the edges of the furniture, making it easier to clean and maintain.

- Cost-effective: Edge banding is often a more cost-effective solution than using solid wood or other materials to cover the edges of the furniture.

- Versatility: Edge banding tape is available in various colors and materials, allowing manufacturers and designers to choose the option that best fits the design and style of the furniture.

Steps for Applying Edge Banding

Several methods apply edge banding to furniture, including manual application with a hand-held iron, automatic application with a specialized machine, and self-adhesive edge banding tape applied with a roller or iron. Here is a general overview of the process for manual edge banding using a hand-held iron:

Prep the edges: Before applying the edge banding, the edges of the furniture should be sanded smoothly and cleaned to remove any dust or debris.

Cut the edge banding: Measure and cut the edge banding to the appropriate length, leaving a small overlap at the corners.

Apply heat: Preheat the hand-held iron according to the manufacturer’s instructions and place it on the edge banding tape. The heat will soften the tape, making it more pliable.

Apply pressure: While applying pressure to the iron, move it along the edge of the furniture to bond the edge banding tape to the surface. Pay particular attention to corners and edges to ensure a seamless transition.

Trim excess material: Once the edge banding is applied, use a sharp blade or edge trimmer to trim any excess material.

Finish the edges: Sand the edges of the furniture to smooth out any imperfections and apply a finish, if desired.

Bottom Line

Edge banding is an important process in furniture production that helps improve the appearance, durability, and maintenance of the finished product.

Edge Banding Services provide high-quality edge banding services for furniture manufacturers and designers. They have a team of experienced professionals dedicated to delivering seamless, smooth transitions from the edge of the furniture to the edge banding material, ensuring that the finished product meets the highest standards of quality and aesthetics.