Description

Veneer Sheets

The manufacturing process defines quality in wood and laminate veneer sheets. ESI is proud to offer a comprehensive line of wood veneer sheets sourced from the USA’s best factories. We have partnered with these manufacturers to offer a wide variety of wood species options while being mindful of responsible growing and harvesting techniques. Our veneer sheets are laminated to a resin impregnated backer sheet, which ensures a reliable backer-to-face bond. This sheet is manufactured to reduce blistering, warping, cupping, splits, and cracks. We also offer other types of backer substrates. Please call for more specific information.

FSC® products available on request

Veneer Cuts

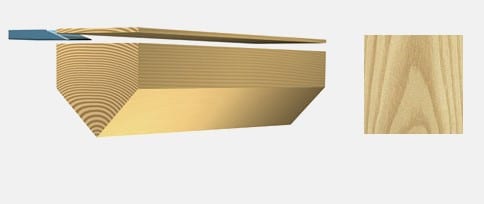

Flat Cut

Flat cut, flat sliced, crown cut, or plain sliced are synonymous terms used in different countries. The half log (flitch) is mounted with the heart side away from the knife against the slicer’s flitch table. The slicing is done parallel to a line through the center of the wood log. This produces a distinctive ‘cathedral,’ or heart figure. The ratio of quartered to crown faces produced by this method naturally runs about 60-40% in favor of the crown.

Plain slicing produces the slicing methods’ largest width veneer as a wood log is cut into two flitches before slicing. The other slicing methods use wood logs that have been cut into several flitches before slicing.

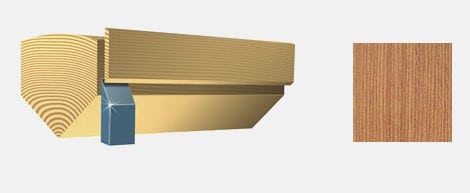

Quartered

Quarter slicing involves first cutting the wood log into four pieces. Then the manufacturer places the quarter log (flitch) on the flitch table so that the growth rings of the wood log strike the knife at approximately right angles, producing a series of stripes, straight in some species, varied in others. The veneer sheet’s width produced through quarter slicing is less than plain slicing, with an average less than 8 inches – depending on log size. The ‘flake’ appearance in oak is produced by the quarter slicing method.

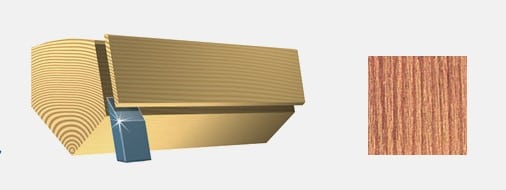

Rift Cut

A rift-cut veneer sheet is produced from the various species of oaks. The wood logs are cut into four pieces.

Rift-cut veneer has a straight-grained look, which is obtained by periodically changing the cutting angle to stay about 15 degrees off the quartered position to avoid the ‘flake’ figure. The veneer sheet’s width produced through rift-cutting is less than plain slicing, with an average less than 8 inches – depending on the wood log size.

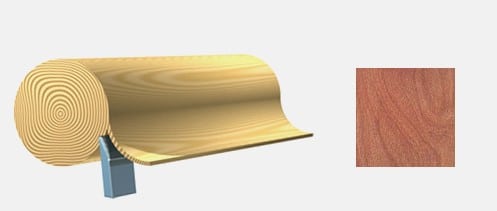

Rotary Cut

In rotary cutting, the wood log is mounted centrally in the lathe and turned against a knife, as if unwinding a roll of paper. A multi-patterned wood grain marking is produced with this method. Rotary cut veneer sheets can be sufficiently wide to provide full sheet faces (one piece).

Veneer Thickness

10 MIL

10 mil backed veneer is very flexible and easy to work with, making it the solution for wrapping contours and shapes. Choose from a variety of domestic and exotic woods.

- Cuts with scissors

- Applies in seconds with glue, contact cement, or hot melt

- Available non-glued or with 3M® pressure-sensitive adhesive

- Standard 4′ x 8′ and 4′ x 10′ sheets available

- Also available in 2′ x 3′, 2′ x 4′, 2′ x 8′, 2′ x 10′, 3′ x 10′

- Special sized sheets available upon request

20 MIL

20 mil laminate has a semi-rigid back which provides an excellent surface bond. 20 mil laminate backer is thicker to eliminate telegraphing and sand through and is suitable for wrapping columns and curved panels.

- Pre-sanded and stress relieved

- Thicker to eliminate telegraphing and sand through

- Suitable for wrapping columns and curved panels

- Available non-glued or with 3M® pressure-sensitive adhesive

- Standard 4′ x 8′ and 4′ x 10′ sheets available

- Also available in 2′ x 3′, 2′ x 4′, 2′ x 8′, 2′ x 10′, 3′ x 10′

- Special sized sheets available upon request

30 MIL

For the roughest of substrates, 30 mil has excellent coverage and durability. It’s an excellent choice for applications using a flat surface or projects not requiring a high degree of flexibility

Wood On Wood (2-ply Backer)

Genuine wood veneer with a polymer resin impregnated backer

- Excellent moisture resistance

- Performs like Phenolic backer

- Easy to apply

- Does not dry out and become brittle

- Less damage from handling

- No added formaldehyde

- Backer has been rated Class A for Flame Spread

- In stock in most popular sized sheets and wood species

Flexwood® Polyback

Genuine wood veneer with a polymer resin impregnated backer

- Excellent moisture resistance

- Performs like Phenolic backer

- Easy to apply

- Does not dry out and become brittle

- Less damage from handling

- No added formaldehyde

- Backer has been rated Class A for Flame Spread

- In stock in most popular sized sheets and wood species